Digitalisation Is The Secret To Traceability - Right First Time Ingredients Drives Finished Product Quality

Traceability is key for any manufacturing process. Regardless of whether you are a food and beverage manufacturer, a pharmaceutical company or creating paints and coverings, it is vital that you track the constituent parts of your finished product and can trace these back to source ingredients.

Why Is Traceability Such A Challenge

Accurate traceability continues to be a major challenge for manufacturers, simply because most of the tracking is done manually and there are so many steps where things can go wrong.

For example, if you are performing manual powder weighing of ingredients, how do you know that each ingredient comes solely from the same batch? What happens if the operator records the wrong details or wrongly labels the dosed batch?

The challenge does not stop there; tracking the ingredients through your production line can be a little like following which cup has the coin under it, and then when your finished product flows off the production line, how confident are you that it has the right label and the right batch code?

The Answer Is Digitalising Traceability

Works orders from SAP are tracked and visualised through a bakery

Like every other sector, manufacturing is on a journey of digitalisation, connecting processes together and seamlessly flowing data between these electronically. For manufacturing, this has not been as easy compared to other sectors, as there are still many tasks that are fully manual and a reliance on operatives to pass data from one step to another naturally introduces high occurrences of errors.

Most manufacturers now have ERP and specialist manufacturing systems in place that can track the process from start to finish; the challenge is how you integrate what is physically happening with what digitally is thought to be happening.

Automating Powder Weighing

Let’s start at the very beginning of the process: powder weighing of source ingredients and batching. OAL’s APRILTM Robotics is fully automating this process; each source ingredient is kept separate, with no cross-contamination, so as the robotic arm weighs out each batch, an accurate record is kept of the constituent parts.

With the ability to integrate this into both ERP and manufacturing systems, the APRIL solution takes human intervention out of the equation. Each batch is uniquely coded and the component of each batch along with their origins are automatically captured.

This means that your manufacturing process starts with the right data that can then be automatically tracked across the entire process.

Labelling & Verification

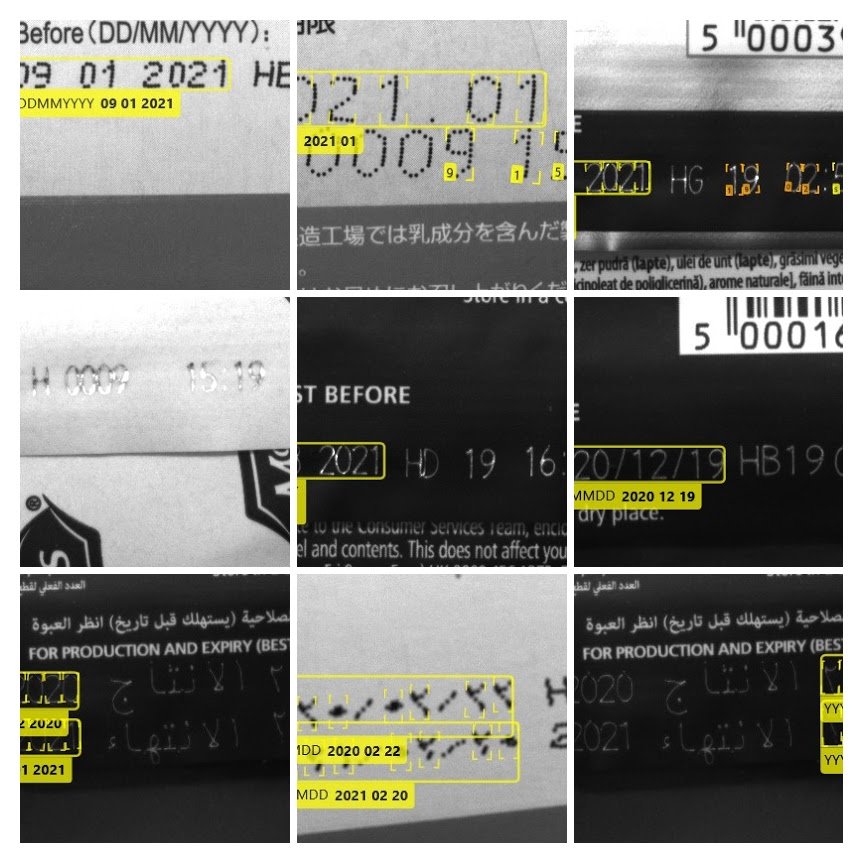

Date code verification with AI based vision using APRIL Eye

At the other end of the process, we have the challenge of ensuring that the finished product has the right label on it, whether that be a container of soup or a pot of paint. The fact that you have accurate traceability data flowing digitally through your manufacturing system while the produce flows down your production line, you can be confident in knowing the contents of each product. The challenge now is ensuring it is labelled correctly.

Step one is tight integration into your ERP and/or manufacturing system to ensure that the correct data is being used to generate the label. For instance, if you’re printing county of origin (COO) information you need to ensure you can track COO to the batch/works order. Having a smart labelling solution is also key. At OAL, we provide solutions to not only ensure labels are produced in line with legislative and your customers’ requirements, but also verify that what should be printed is actually printed using APRIL Eye.

The final step is ensuring that the right label is placed on the right container or packaging; here again OAL label verification solutions integrate tightly with the ERP and/or manufacturing system so at the end of the production line, AI-powered software can be used to take image feeds from cameras and verify that every product leaving your production line is labelled correctly.

Smarter Traceability, Greater Productivity

Digitalising Traceability in the ways outlined above significantly reduces the risk of errors and ensures you can track each batch to the finest detail of its constituent parts.

By automating the flow of data between the manufacturing steps through your ERP/manufacturing system, you eliminate paperwork and many of the manual tasks that currently slow down your production process.

By leveraging the technology available to digitalise this critical part of manufacturing, you can reduce risk and increase the accuracy of traceability while increasing the efficiency and productivity of your end-to-end process.

Read our client success story HERE.

If you would like to discuss more about how these solutions work and how they would be beneficial to your operation, then simply reach out to the OAL team – contact us.

6 Ways To Make Cooking Soups and Sauces More Efficient In Food Manufacturing

Efficiency, taste, and sustainability are paramount in food manufacturing, particularly when producing soups and sauces. Traditional methods often fall short, being labor-intensive and energy-consuming. Discover how Steam Infusion can redefine your production metrics—reach out to the OAL team today.

For food manufacturers, the cooking process is fundamental to producing high-quality finished soups, sauces and other liquid products. However, traditional processes and technologies mean that this can be lengthy, labour-intensive and highly inefficient in terms of energy consumption.

The good news is that this does not have to be the case. Over the past few years, more organisations have transitioned away from traditional steam jacketed kettles to utilising Steam Infusion technology; this is significantly reducing cooking time and cleaning in place (CIP) time while improving the quality of the cooked product. Plus reducing water consumption in the cleaning processes by up to 90%.

How much energy should I be using to cook?

To heat 1,000KG of a typical sauce from 20 to 85 Degrees C require c76 kWh of input energy. A similar amount of input energy is required to clean the vessel using hot water and cleaning solution.

From studies with our partners at the University of Lincoln, real-world usage is considerably higher, with energy consumption varying from 500 kWh per 1,000KG of finished product to 1,200 kWh+.

In the Netherlands, combining Steam Infusion with OALs robotic chef, APRIL has achieved sub 250kWh per tonne of finished product. These technologies form part of a Carbon Trust project to improve efficiencies further as we move towards a net zero economy.

Here we take a closer look at how Steam Infusion cooking can make you more efficient:

What is Steam Infusion cooking?

Steam Infusion is a direct contact heating process whereby steam condenses on the surface of a liquid, gently yet rapidly cooking a range of food and beverages up to a temperature of 140oC. The patented Steam Infusion VactionTM Pump rapidly heats, mixes and pumps food ingredients and products, offering near perfect energy transfer. By varying the steam pressure and flow rate through the pump, the processing conditions change, from gentle cooking to intense mixing and pumping with a homogenising effect,

In simple terms, rather than heating the vessel that the product is in and utilising a secondary mixing process, steam infusion injects the heat directly into the product in-vessel or in-pipe.

Benefit 1: It tastes better

Slow cooking times can lead to loss of vibrant colours and flavours during the cooking process. With Steam Infusion this is not the case, as the rapid heating process ensures that vital nutrients and colour are not simply boiled away but retained. This not only ensures that your finished product tastes great but also enables you to reduce the quantities of ingredients used. For example, we have seen certain products(recipe dependent) achieving a 50% reduction in required spices to achieve the optimum taste.

Benefit 2: Reduced cooking time

Steam Infusion is a far quicker way to cook. For example, a 1,000kg batch of soup can be heated from 20 to 85 degrees C within 10 minutes. When combined with reduced cleaning time and robotic batch processing product through-put can be increased by 6x, driving far greater cooking capacity for manufacturers.

Benefit 3: Reduce Clean-In-Production time

As Steam Infusion is not heating the vessel, but heating its contents, this approach prevents burn-on, which is a major issue that lengthens CIP time. When this is combined with robotic automated pouring, rather than traditional pump and piping technology, the end-to-end cleaning process is simplified and shortened, with a CIP water reduction of greater than 90% not being uncommon.

Benefit 4: Removing Cross-Contamination

Following on from the fact that Steam Infusion prevents burn-on and also enables more effective cleaning, a significant benefit is removing cross-contamination. You eliminate the risk that vessels or pipes being used still have the remanence of your last batch, therefore avoiding compromise of taste and, more importantly, the health risk of cross-contamination of allergens or other ingredients.

Benefit 5: Reduce Energy Consumption

As the cost of energy continues to rise and food manufacturers are under growing pressure to be more sustainable, anything that can be done to reduce energy consumption is a significant benefit. OAL is part of the Souper Green project in partnership with Solina, supported by Marks and Spencer PLC, the Department for Energy Security, and Net Zero’s Industrial Energy Efficiency Accelerator (IEEA). By incorporating a lightweight cooking vessel, this programme provided a more efficient heating operation and easier cleaning, leading to an impressive 80% energy savings from production trials.

Benefit 6: Greater reliability

Any failure of your cooking technology results in a significant loss of production – cooking time is money after all. By removing the complexity of traditional processes and equipment, Steam Infusion is making the whole process more reliable. Less failures result in continuity of productivity, while greater accuracy of the cooking process reduces wastage both of failed batches and reduced quantities, as a result of burn-on.

Steam Infusion is generating some impressive results for food manufacturers across the globe, improving product differentiation factors while delivering tangible operational benefits. We would love to share more with you about the benefits OAL Steam Infusion technology can bring to your operation and to show you how this would work on your recipes in our test centre.

Simply reach out to the OAL team – contact us.

Breaking The Myths of Robots in Powder Weighing

Our focus in this blog is to challenge the myths preventing the adoption of robotic automation in powder weighing and handling. Fear of the unknown and failure often deter progress, but by confronting these misconceptions, we can ease the path towards inevitable automation across various industries.

We all know that one day we will make the move to an electric vehicle; it is inevitable - it is the way the world is going. However, it is estimated that currently only 1 in 250 cars on the road are electric. There are two key factors that hinders change, ‘the fear of the unknown’ and the ‘fear of failure.’

It is a similar story in the world of manufacturing. We all know that the future will be “automated” and in contrast to our digital robotic everyday lives (think smartphones, robotic vacuum cleaners) the pace of adoption of these new technologies in industry can often seem slow due to the same two fears.

When we fear change, the coping mechanism is to create myths…well they are not really myths; they are excuses for not making a decision or taking action. In this blog we look to break some of the so-called myths that are delaying manufacturers from making the inevitable step on the journey to robotic automation.

Our focus is on the area of robotic automation in powder handling and weighing as this is the area in which we are specialists in and it covers a broad spectrum of industries from food and beverage to tyre manufacturers, from cosmetics to paint and coverings.

Myth: We don’t have room in our factory for a robot

One of the benefits of robotic automation is that it can operate in a very compact cell. OAL’s APRIL Robotics standard cell can store 6,000kg and weigh powders in a space of only 7m x 7m which is normally less space than taken up by existing powder weighing operations.

Myth: The powders we work with are too cohesive for automation

The precise movement of the robotic arm and powerful software alogithims means that even the most cohesive powders can be handled accurately. With APRIL, we have tested over hundred of different powdesr types and consistently achieve accuracy of +/-1%, often more. We always welcome organisations to provide samples for us to test.

Myth: We have too many ingredients

Simplifying the complex is where robotic automation excels. A single APRIL cell can store up to 120 different raw materials in the cell with unlimited raw materials stored in ASCs offline. One of the benefits of robots is that they always remember where they have put things, unlike humans.

Myth: We make lots and lots of different batch types

Robots are far better at repetitive tasks than humans as they never get bored or distracted. They are also better than humans at constantly changing batch types. They do not have to learn new recipes; every batch is digitally instructed.

Myth: We don’t have staff who can operate robots

Most manufacturers have packaging line robots and understand the training and maintenance requirements. Using robots upsteam provides opportunities to upskill operatives and engage teams with modern digital technologies.

Myth: The required investment is too great and payback period too long

Most powder weighing applications can achieve a payback in two years through reduced operating costs and improved raw material yield. Other key benefits to consider are improved agility, quality and traceability security, and the reduction in health and safety risks. Add all of these together and an attractive business case can be created.

We would love to hear any other myths you may have about robotic automation, and always happy to discuss these with you. Simply reach out to the OAL team – contact us.

Meet Harry

Celebrate OAL's 30th anniversary by getting to know our founder, Harry Norman. A visionary who fell in love with robotics, Harry saw its potential in the food and beverage industry and founded OAL at just 28. His knack for innovation led to groundbreaking solutions like OAL Connected and Steam Infusion, transforming food manufacturing. Today, Harry's passion for robotics and automation continues to drive OAL's success.

This year, OAL will be celebrating its 30th birthday, so we thought it would be fitting to turn the spotlight on our founder and share a little about our very own Harry Norman.

The story begins, as Harry puts it, "when he stumbled on a robotics course at Coventry University." He instantly fell in love with the technology to which he was exposed and quickly saw its potential for application in the food and beverage industry; this sparked the entrepreneur within him.

For most people, being newly married with two young children to support might discourage them from following their dream, but not Harry. He was excited and convinced he could make a difference, so in 1993, at just 28, he founded OAL.

Initially, Harry's company developed software for machine builders and directly for food manufacturers. It quickly became successful, delivering profit within its first year of operation.

The Early Years

Propelled by customer demand for automation, Harry evolved OAL to offer turnkey processing solutions and quickly established a customer base that included some of the leading brands in the food and beverage sector.

Harry's extraordinary talent lies in innovation – the ability to look at something and instantly see a better way of doing it. Where others might walk past a process on a factory floor, dismissing it as 'the way it has always been done,' Harry sees all the inherent problems and immediately considers what could be possible. This ability has led to a wide range of innovations that have been instrumental to OAL’s success.

In 2001, Harry identified the significant risk associated with the labelling of food items. OAL set to work and launched OAL Connected – an automated way to verify labels and data coding on food packaging. This has become a market-leading solution for OAL, preventing labelling errors across 1,200+ food packaging lines, including leading manufacturers like Bakkavor, Pilgrim’s Food Masters, and Worldwide Fruit.

Full Steam Ahead

Harry is driven by success; each innovation that makes a difference only motivates him to strive for the next solution that will disrupt for the better. Observing an industry that was facing rising labour costs and increasing ingredient prices, Harry was convinced that food manufacturing needed to change. He believed that OAL could play a key role in driving such change and decided to set-up a dedicated innovation team and invest in new technologies that could make a difference.

The first result of this investment in R&D was ‘Steam Infusion’ that OAL launched in 2013. This heating, mixing and homogenising technology uses steam as the motive force delivering significant benefits over the traditional steam jacket cooking process. With the ability to double cooking capacity and develop exciting new food products, OAL’s Steam Infusion is now being used by food manufacturers across the globe.

Robotic Automation

While continually looking to spot trends and opportunities for change in the manufacturing process, it would appear that Harry never forgot that Robotic course at University. Today, OAL is leading the market with its APRIL Robotics solutions that look to automate many steps in the food manufacturing process, radically improving productivity, food safety and traceability.

OAL’s APRIL is being used to modernise powder weighing and batching and to automate key steps in the cooking process.

Thirty years on, Harry’s passion has not wavered; if anything, his desire to innovate and make a difference has only grown. The capabilities of APRIL Robotics is applicable to many other industry sectors from cosmetics to tire manufacturing, from paints to pharmaceuticals. As Harry’s company goes from strength to strength, he gets closer to his vision of transforming sustainability and manufacturing operations with robotics and automation.

If you would like to discover more about our innovations and how they would be beneficial to your operation, then simply reach out to the OAL team – contact us.

Top 5 Reasons to Automate Powder Weighing

Self-contained pods capable of storing 100+ raw materials, along with a central robot for automatic ingredient selection, weighing, and pouring, have digitalized and modernized the crucial Powder Weighing step in manufacturing. This automation offers key benefits you should be aware of.

Whether you are manufacturing food, beverages, cosmetics, paint or even tyres, step one of your process is likely to be powder weighing. Taking all of the raw materials and combining the right quantities of each of these to create your batches for processing.

Traditionally, this has been a manual task; sacks, drums, scales, scoops and a lot of powder scattered all over the place. However, while William or Wilhelmina the weighers have been sweeping up the spills, technology has been happening to create AI-driven Robots to automate and modernise powder weighing.

Self-contained pods that can store over 100 raw materials, with a central robot that can automatically select, weigh and pour ingredients into accurate batches for processing, robotic Powder Weighing is enabling this critical step in the manufacturing process to be digitalised, automated and modernised and this is delivering some fundamental benefits that you should know about.

Here the top 5 reasons manufacturers are automating their powder weighing process.

1. Address Operative Health & Safety

Powder weighing is a hazardous task, even innocuous ingredients can be an irritant if repeatedly inhaled and as for toxic substances, regardless of the precautions you take, there is always a risk to health. By taking operatives outside of the weighing zone and replacing them with a robot, you fully address your duty of care and remove the risk. (Read more)

2. Scale Productivity

It goes without saying that a robot does not take holidays, is never sick and does not require lunch breaks. They can also run 24x7 ensuring they are always ahead of demand and never hold up your production line. This increases throughput while reducing labour costs and dependences. One robot running 24x7 can be the equivalent of 10 to 20 operatives when shifts, holidays and sickness are taken into account.

3. Improve Accuracy/Reduce Waste

It is not just about the spillage in manual operations, it is about the cost of getting it wrong. When an error occurs in the weighing and batching process, this is often only caught at the end of the production cycle creating wastage of both raw materials and processing time. With Robotic Weighing, human error is eliminated, the robot never gets tired or distracted and they weigh accurately every single time to within 1g.

4. Digitalise Traceability

Across every industry, traceability of source ingredients is critical. If there is an issue, it needs to be traced back to source, identifying any other batches that could be at risk, and driving continuous quality improvement. By eradicating paper and manual tracking, you are able to drive far better and more granular traceability. Through seamless integration of the Robot Weighing system with your manufacturing/production system, every batch can be tracked and analysed against its source ingredients.

5. Prevent Cross-Contamination

Anyone who has walked past the powder weighing area is well familiar of the risk of cross-contamination; it is inevitable with manual scooping and even when some form of piped dosing is being used. The precision of Robot Weighing and batching removes all of these points of cross-contamination, preventing it happening and significantly reducing risk.

These five points are just some of the ways that robotic powder weighing is delivering significant value and benefits to manufacturers. We know this because OAL is the leading innovator in this area and are helping organisations across a wide variety of sectors to modernise powder weighing to drive greater efficiency across their operation.

If you would like to discuss more about how these solutions work and how they would be beneficial to your operation, then simply reach out to the OAL team – contact us.

Pre-Weigh Automation is Key to Resolving Labour and Safety Challenges in Personal Care Manufacturing

Personal care manufacturing has two big problems on its hands: not enough workers and the need for safer working conditions. These issues meet head-on in pre-weigh operations - an area that hasn't seen much digital change yet.

This key area of production, traditionally reliant on manual labour, has its fair share of safety concerns and efficiency issues. However, there's a clear answer to these challenges: automation.

Personal care manufacturing has two critical risks: insufficient workers and the need for safer working conditions. These issues meet head-on in pre-weigh operations - an area that has seen limited digitalisation.

This key area of production, traditionally reliant on manual labour, has its fair share of safety concerns and efficiency issues. However, there's a clear answer to these challenges: automation.

Confronting the Labour Shortage Head-On

Shortage of workers isn't just a small problem, it's a serious concern. Manual pre-weigh processes require multiple workers per shift, which is neither sustainable nor efficient in the current scenario. Here's where the APRIL™ Robotics System steps in, automating these laborious processes, and freeing up your workforce for areas that cannot be automated, and truly need human insight and intervention. This ensures that production levels remain steady, irrespective of fluctuations in labour availability.

A Direct Response to Safety Concerns

Safety is not a matter to be taken lightly. Manual pre-weigh operations involve regular exposure to powders and potentially harmful raw materials, posing clear health and safety risks. The answer to this is as clear as it is urgent: automation. By incorporating the APRIL™ Robotics System into these operations, we can significantly reduce exposure to potential hazards. With its guarantee of precise dosing and reduced human intervention, the system minimises the risk of operator error, injuries, and fatigue. This simple solution enhances both employee wellbeing and overall company performance.

Customer story: Explore Agrana Fruit's transformative journey from manual to automated weighing, reducing workplace safety concerns and cross-contamination issues with April Robotics' weighing system.

Increasing Accuracy and Efficiency: No Half Measures

In the personal care manufacturing industry, there's zero tolerance for error or inefficiency. However, manual pre-weigh processes can often leave room for inaccuracies and inconsistencies. That's where the APRIL™ Robotics System comes into play. With its precise, repeatable measures, it offers a direct solution to these problems, reducing waste, minimising error, and ultimately leading to cost savings.

Real-time Data Integration with ERP Systems: The Key to Smoother Operations

The APRIL™ Robotics System isn't just an automation solution; it's a gateway to a more streamlined, data-driven approach to manufacturing. With the ability to integrate with Enterprise Resource Planning (ERP) systems, the system offers real-time data insight, contributing significantly to smoother, more informed decision-making processes. This integration with ERP systems makes your entire operation more transparent and efficient and can significantly simplify managerial oversight and quality control.

In essence, the APRIL™ Robotics System presents a clear, compelling solution to the labour shortages and safety challenges currently facing the personal care manufacturing industry. The benefits are significant: enhanced safety, improved accuracy, increased efficiency, and streamlined data management. With the mounting pressures of labour shortages and health and safety demands, the way forward is clear and necessary: it's time to modernise and automate pre-weigh operations.

Why Every F&B Manufacturer Needs Automated Packaging & Labelling Alongside Date Code Checks

As a responsible food and drink manufacturer, you understand the significance of delivering safe and trustworthy products to consumers worldwide. Customers trust your brand to give them safe, tasty products, and they want to know they can trust what's on the label. That’s why automated packaging and label verification alongside date code checks play a crucial role, serving as your dedicated quality control team to guarantee perfection.

As a responsible food and drink manufacturer, you understand the significance of delivering safe and trustworthy products to consumers. Customers trust your brand to give them safe, tasty products, and they want to know they can trust what's on the label. This is where automated packaging and label verification alongside date code checks play a crucial role, serving as your dedicated quality control team to guarantee perfection.

Why You Need Automated Packaging and Label Checks

When you're making hundreds, thousands, or even millions of items, it's hard to keep an eye on every single one. But your customers are counting on you to get it right. If a package goes out with the wrong label or missing information, it could be dangerous or even life-threatening to someone with allergies. Plus, if you're an own-label manufacturer, most retailers, including Marks and Spencer and Sainsbury’s, require a continuous online verification system.

With automated packaging and label verification system, you can check every single item you produce to make sure it's packaged and labelled correctly.

How OAL automated packaging and label verification works: We install cameras on your production line that scan every package. They check it against the job you're running and if something's not right, they'll stop the line so you can fix it. It's like having a second pair of eyes that never get tired or distracted.

The system stops the line and alarms if there is a fail-safe fault including:

Wrong packaging detected

Excessive no reads, product detected but no barcode found

Sensor failure

It's not just about safety and law either. If your products always look perfect and professional, it's good for your business. People are more likely to trust and buy from a brand that looks like they've got their act together.

Watch how the automated label verification works:

Why You Need Date Code Verification

Accurate date codes are equally crucial. They inform retailers and customers about the product's manufacturing and expiry dates, preventing early spoilage or unnecessary discarding of perfectly good stock. Incorrect date codes can tarnish your reputation and adversely affect your bottom line.

The good news is OAL has a system for this too. Our system configures your printers to ensure the accurate printing of date codes for each job, eliminating human errors like typos or incorrect printer settings.

Our AI vision system, known as APRIL Eye, meticulously inspects every date code to ensure correctness and legibility. It adapts effortlessly to different fonts, sizes, and positions, showcasing its exceptional versatility.

Wrapping It Up

So, why do you need automated label and packaging verifications alongside date code checks? It's simple: to make sure your customers can trust your products, to follow the law, and to keep your products looking their best. It's all about taking pride in what you do and making sure you're delivering the best for your customers.

At the end of the day, OAL's systems are there to help you do just that. Need help? Let’s have a chat.

5 Compelling Reasons to Prioritise Pre-Weigh Automation in Your Next Personal Care Digitalisation Initiative

Industry 4.0's wave is reshaping the personal care sector, merging the digital and physical worlds to create smart factories. However, this digitalisation journey often neglects a crucial stage - pre-weigh operations, which remain labour-intensive and unchanged. As part of the industry's nascent digitisation, it's crucial to prioritise pre-weigh operations automation, providing a springboard towards operational excellence.

Industry 4.0 is opening up fresh and exciting opportunities in the personal care sector, making operations more streamlined and efficient. It's bringing our digital and physical worlds closer together, paving the way for smart factories as the next big thing in manufacturing. The first significant move? Upgrading an often-ignored area: pre-weigh operations.

Pre-weigh operations currently feel a bit old-fashioned, still heavily reliant on human work and untouched by the digital age. Typically there are over 400,000 powder additions by hand per year. This stands in stark contrast to the advanced automated packaging lines we use today. But this manual step in the process is ripe for digital transformation. A standard APRIL™ Robotics Weighing System can automatically dose 500,000 powder additions per year. Here are five compelling reasons to automate the pre-weigh process:

A pre-weigh area before and after robotic automation

Health & Safety is Paramount

Regular exposure to powders, dust, and potentially carcinogenic ingredients present significant health and safety risks to operators. Automating pre-weigh operations can vastly reduce these hazards. The APRIL™ Robotics System ensures precise dose of every powder, reducing chances of operator error, injuries, and fatigue. A safe, efficient workspace improves not only staff wellbeing but also the performance of the company.

Boost Efficiency

Many personal care companies embrace “lean manufacturing”. Pre-weigh is the first step in the manufacturing process. Downstream constraints in either mixing or packing are elevated ensuring they are always served right-first-time raw materials, eliminating downtime.

Better Yield and Precision

Automating pre-weigh processes can lead to significant improvements. Having an accurate recipe from the start makes the process reliable and efficient, reduces waste, and maximises return on investment. The APRIL™ Robotics Weighing System uses proven weighing algorithms to accurately dose and handle even the trickiest ‘non-free flowing’ raw materials, down to +/- 1 gram.

Assured Quality and Traceability

Modern consumers want to be confident in what they're buying. With the APRIL™ Robotics' automated weighing and powder dosing systems, personal care manufacturers can ensure each powder is dosed correctly the first time. This eliminates human error, provides traceability, and helps earn consumer trust.

Bonus: Embracing the Power of AI and Just-In-Time Manufacturing

AI-based scheduling can make operations more dependable and adaptive, which are vital features of just-in-time manufacturing. The APRIL™ Robotics System can directly receive orders from your ERP, automate over 500,000 manual powder additions per year, and even offer protection of IP by removing the need for operators to know the constituents of any formulation, thereby securing your "secret sauce".

Conclusion

In a nutshell, in the fast-moving world of personal care manufacturing, digitalisation is key. To remain competitive, pre-weigh automation must be embraced, paving the way towards improved safety, reliability, and profitability. The vision is clear: integrating automated pre-weighing into your digitalisation strategy is the catalyst towards leaner, safer, and more productive operations.

With APRIL™ Robotics, we can not only revolutionise pre-weigh operations, but also speed up full-scale factory digitalisation.

Simply put, digital adoption is less a choice than a competitive imperative. APRIL™ Robotics stands ready to guide you through smart factory transformation, stepping confidently towards Industry 5.0.

Protecting Workers' Health: The Call for Powder Handling Automation in Food Manufacturing

The food industry is constantly evolving, and companies that recognise the importance of worker safety and well-being are leading the way. However, protecting workers from the risks of powder exposure has always been a challenging task. Often, traditional solutions to these risks are not practical or cost-effective. Fortunately, with the advent of robotics and automation, a solution is now available.

Urgency to Embrace Powder Handling Automation

The food industry is constantly evolving, and companies that recognise the importance of worker safety and well-being are leading the way. However, protecting workers from the risks of powder exposure has always been a challenging task. Often, traditional solutions to these risks are not practical or cost-effective. Fortunately, with the advent of robotics and automation, a solution is now available.

Manual powder handling processes such as scooping, pouring, and weighing have been an integral part of the industry for decades. However, these processes put workers at risk of respiratory problems, lung damage, and cancer caused by exposure to hazardous powders. By investing in powder handling automation, companies can reduce the risk of exposure and ensure that their workers can work in a safe and healthy environment.

Beyond Respiratory Health: The Overlooked Impact of Dust Exposure in Food Manufacturing

The F&B manufacturing industry faces significant challenges when it comes to health and safety. According to HSE, respiratory diseases account for 12.5% of all occupational disease cases in the industry, with 12,000 new cases reported annually. In the food industry, occupational asthma accounts for 33% of compensation cases, with bakers being the second most affected group as reported by the Department of Work and Pensions Industrial Injuries Scheme. Dust from grain, flour, bakery dust, egg protein, fish protein, etc., are the primary culprits. These hazards can cause eye irritation, skin irritation, allergies, and other respiratory issues.

These symptoms can significantly impact a worker's quality of life and, in some cases, can even lead to long-term health problems.

Full automation is the solution. Automated systems, like those offered by OAL, significantly reduce workers' exposure to dust and other harmful particles, providing a safer and healthier workplace.

A Smart Investment: How Powder Handling Automation Can Boost Worker Health and Manufacturing Processes

Investing in powder handling automation not only protects workers' health but also brings several other benefits for both worker safety and manufacturing processes. Below are some of the key benefits of powder handling automation:

Benefits for Worker Health and Safety:

Reduced dust exposure - Automated powder handling systems eliminate the need for manual processes such as scooping, pouring, and weighing, significantly reducing workers' exposure to dust and other harmful particles that can put their health at risk.

Improved air quality - Advanced filtering systems in automated powder handling systems capture and eliminate any dust generated during the handling process, improving air quality, and reducing the risk of respiratory problems.

Safer workplace - With over 1,700 acute injuries reported every year, powder handling automation is a game-changer. By eliminating the risk of accidents and injuries associated with manual powder handling processes, automated systems provide a safer workplace, preventing back injuries and other occupational hazards.

Benefits for Manufacturers:

Increased efficiency - Automated systems ensure that the correct amount of powder is dispensed every time, eliminating the risk of over or under dosing, which can lead to product quality issues. Automated systems also have a higher throughput capacity, reducing production time and increasing efficiency.

Reduced waste - Automated powder handling systems accurately dispense the correct amount of powder, reducing waste and improving overall product quality.

Improved product quality and IP protection - Automated systems guarantee precise and consistent dosing, resulting in high-quality products that meet desired specifications and food compliance standards. By limiting access to the system, automation can also prevent unauthorised changes to the recipe, reducing the risk of errors and cross-contamination. This, in turn, enhances intellectual property (IP) protection by providing a reliable and traceable record of production.

Investing in powder handling automation is not only a smart business decision but also the best thing to ensure better efficiency and safety in operations. Protecting worker health and safety is a top priority for all organisations, and automated powder handling systems provide an effective solution for reducing dust exposure and improving overall workplace safety. The improved product quality provided by powder handling automation can also have a significant positive impact on a company's bottom line.

OAL's Innovative Solution for Doughnut Bakery: Protecting Workers' Health and Elevating Product Quality

Automated powder handling systems are a smart business investment. OAL's innovative solution for a doughnut bakery demonstrates how powder handling automation can significantly enhance worker health and safety while improving product quality. The system, which features three big bag stations with sifting, eliminates the incorrect batching of ingredients and minimises the loss of ingredients during transfer.

Image on left: The new silo designed and installed by OAL at the bakery

Image on right: Three Big Bag stations with Sifting

While small recipe additions are still made manually, the system's advanced features, such as an HMI and recipe management system, simplify monitoring of the production line and automate ingredient additions. This reduces the need for manual labour and minimises worker exposure to harmful particles.

Furthermore, commissioning and certification ensure that the system operates as required, and post-installation support is provided to ensure a smooth and efficient production process. The solution has enabled the doughnut production line to store and transport dry and liquid-based ingredients more efficiently, providing a safer and healthier working environment for bakery workers while ensuring high-quality products for consumers.

Explore the full case study here.

By embracing automation with APRIL, manufacturers can improve product quality and efficiency while addressing health and safety concerns for operators. With robots performing heavy lifting, musculoskeletal disorders can be avoided, and operators can be trained for more value-added roles such as controlling robots or maintaining equipment. The challenge will be to ensure that our workforce has the right skills to meet this future vision.

Building A Better World with Industry 5.0

Industry 5.0, the era of ‘Human-Tech Collaboration,’ merges the latest technological advances with human expertise to achieve the best of both worlds. By combining Industry 4.0's technological innovations with value-driven, human-centric initiatives, Industry 5.0 facilitates a seamless and collaborative interplay between people and machines, resulting in a high capacity, more sustainable, safe, and human-centric approach to food and beverage manufacturing.

The new industrial revolution will focus on celebrating workers and making technology work for them, not the other way around.

Discover more about how Industry 4.0 and 5.0 are transforming the future of food and beverage manufacturing and learn about the megatrends driving the shift towards the factory of the future in our exclusive report here.

The Responsibility of the Food Industry: Prioritising Workers' Health through Powder Handling Automation

The industrial revolution is entering a new era with Industry 5.0, where human and technology collaborate for a safer, sustainable, and equitable workplace. The food and beverage manufacturing industry is stepping up to this challenge by adopting robotics and automation for hazardous manual tasks like powder handling, weighing, and ingredient dosing. By embracing full automation, the industry not only reduces workers' exposure to harmful particles and dust but also improves efficiency, reduces waste, and enhances product quality. It is time for the industry to prioritise worker safety and take proactive measures towards Industry 5.0 for a better future.

The Future of Food Safety: How Robotic Automation is Taking on Food Contamination

The use of robotics and automation is gaining immense popularity in the food and beverage industry, with the potential to revolutionise how food is produced, processed, and delivered. Automation systems are playing a pivotal role in reducing the risk of contamination by minimising human intervention and improving product traceability.

The world is currently locked in a perpetual battle with food safety issues, as contamination incidents and food scandals consistently endanger public health and shake consumer confidence. Unsafe food costs low- and middle-income countries a staggering US$ 110 billion annually in productivity and medical expenses. Food safety is a critical concern for consumers, especially those with food allergies. It is imperative that manufacturers ensure that the right ingredients in the right quantities are used in their products. Incorrect or undeclared ingredients can have serious health consequences, as seen in recent incidents such as Pret's undeclared sesame allergy. Such recent high-profile food contamination incidents across the world serve as a reminder of the need for innovative solutions to preserve food integrity and security.

Fortunately, there is a revolutionary solution to combat food contamination and improve food safety standards through the use of robotics and automation. While traditional methods have been utilised to mitigate the issue, the use of robotic automation presents a transformative solution.

This article explores how robotics and automation are helping to combat food contamination, and the benefits they provide to manufacturers and consumers alike.

The Crucial Importance of Food Safety and Integrity

The World Economic Forum has emphasised the immense impact of food safety on public health, economic growth, and social stability. As such, food safety and integrity are integral components of the food and beverage industry, influencing both consumer confidence and public health. The achievement of ambitious standards of food safety and integrity requires a comprehensive approach that covers all aspects of the food supply chain, from farm to table. This approach includes the implementation of effective hygiene practices, the enforcement of stringent quality control measures, and ensuring traceability and transparency in the production and distribution of food products. Prioritising food safety and integrity not only safeguards consumers but also improves brand reputation, resulting in a more sustainable and responsible food system.

The Food Contamination Challenge

Food contamination is a persistent challenge facing the food and beverage industry worldwide, as demonstrated by recent product recalls. In 2020, food manufacturers in the UK experienced multiple recalls due to poor food quality, undeclared allergens, and other forms of contamination. These recalls underscore the critical need to maintain high standards of food safety and integrity in the industry. Similarly, in the United States, Tyson Foods, Nestle USA Inc., and other manufacturers also faced product recalls, resulting in substantial financial penalties and significant harm to their reputations.

These recalls serve as a reminder of the critical need to maintain high standards of food safety and integrity in the industry. They underscore the importance of implementing robust measures to prevent food contamination through proper ingredient mixing and usage in manufacturing process and ensure product traceability. Food manufacturers have a responsibility to ensure that their products are safe and free from harmful contaminants. Neglecting this responsibility may result in legal and financial consequences, as well as damage to their brand reputation and loss of consumer trust. Ultimately, the failure to protect consumers from food contamination could have serious health consequences, making it crucial for food manufacturers to prioritise food safety and integrity.

Embracing Robotic Automation as a Solution

The use of robotics and automation is gaining immense popularity in the food and beverage industry, with the potential to revolutionise how food is produced, processed, and delivered. Automation systems are playing a pivotal role in reducing the risk of contamination by minimising human intervention and improving product traceability. Robots are now extensively used for sorting, grading, and packing tasks, resulting in improved efficiency and reduced risk of cross-contamination. Additionally, automated systems can detect any defects or contaminants in food products before they reach consumers, ensuring that only high-quality products are delivered to the market.

One area where robotic automation solutions - like APRIL Robotics - have proven particularly useful is in the handling of raw materials and ingredients. This is a critical component of food safety, and our technology has demonstrated how robotic automation can significantly improve the accuracy, efficiency, and quality of ingredient handling across the supply chain. Our APRIL Robotics Weighing System has been utilised by Agrana Fruit, leading to a step-change in safety, quality, accuracy of weighing, and efficiency.

By automating the previously manual process, Agrana Fruit achieved improved product safety and consistency while reducing the risk of contamination. Automated systems ensure that raw materials are safely stored and handled, minimising the risk of contamination, and can help to ensure that ingredients are accurately weighed and mixed, reducing the risk of errors and inconsistencies in the final product. Furthermore, robotics and automation can aid in reducing waste and improving sustainability by optimising production processes and minimising energy and water usage.

Boosting Traceability and Hygiene: The Benefits of Robotic Automation in the Food Industry

The Implementation of Robotic automation in the F&B industry offers numerous benefits:

Enhanced Precision and Traceability: Precision and accuracy are critical in the production of food products, and automation can help manufacturers achieve this. Automation allows manufacturers to create consistency in their products, reduce the risk of contamination, and increase production efficiency. This process can be carried out using advanced software and sensors to control the manufacturing process and ensure that the correct ingredients are used. Robotic automation also offers accurate and consistent weighing and handling of ingredients, significantly reducing the risk of contamination. Additionally, automation technology provides real-time monitoring of ingredient sources, enhancing food traceability. OAL's APRIL Robotics Weighing System allows manufacturers to perform weighing and handling tasks more accurately, efficiently, and faster than human operators, with zero errors or waste. This increases productivity, reduces costs, and makes the business more competitive.

Improved Hygiene and Contamination Prevention: The daily exposure to powder and dust represents a significant health and safety risk. To mitigate the risk associated with manual handling, the removal of humans from the task is crucial. Robotics and automation offer a reliable solution, as they operate in highly regulated environments, minimising cross-contamination risks, and ensuring food processing facilities comply with rigorous hygiene standards.

Optimised Production and Waste Reduction: Robotic automation streamlines repetitive tasks, expedites production time, and minimises waste, resulting in lower production costs and improved product quality. Automated systems can also optimise production processes, reducing energy and water usage and minimising the environmental impact of food production.

Restored Consumer Confidence: Recent food scandals have weakened consumer trust in the food industry. Robotics and automation can boost food safety, decrease contamination risks, and restore consumer confidence. By automating previously manual weighing operations, the risk of human error is reduced, resulting in consumers feeling more confident in the products they purchase.

OAL's Robotic Automation: Revolutionising Food Safety Measures

The global challenges of food contamination and integrity still persist, posing a serious threat to public health and consumer confidence. Adopting robotic automation is the solution to this pressing issue, as it can enhance precision, traceability, and hygiene, while fortifying the food supply chain.

As the global population grows, there is an increasing demand for efficient, sustainable, and safer food production. To meet this demand, the food and beverage manufacturing industry is embracing innovative technologies like robotics, automation, and AI. By combining these advances with value-driven, human-centric initiatives, the Industry 5.0 era has begun, facilitating a seamless and collaborative interplay between people and machines. This approach leads to a high-capacity, sustainable, safe, and human-centric approach to food and beverage manufacturing. Check out our special trends report to learn about the latest megatrends in the food and beverage manufacturing industry.

As the world faces ongoing food safety challenges, adopting advanced technology is crucial to ensure a safer and more sustainable food system for future generations. At OAL, we are committed to this mission, tirelessly working to improve the way food is made and make it safer for consumption both today and in the future.