APRIL™ Eye - AI Vision Systems for Food Manufacturing

Improve inspection, reduce errors and increase traceability with powerful AI vision systems fully integrated by OAL.

Why APRIL™ Eye is the standard for AI vision in food manufacturing

Proven performance. Seamless integration. Trusted by the UK’s top food manufacturers.

Verify printed text

From ingredients to date codes, APRIL Eye has you covered

Seamless integration

Easily integrates with your existing production lines, minimising downtime

Visual Quality Control

Check your product quality and packs with powerful AI inspection

Automated reporting tools

Generate inspection logs and exception reports automatically for compliance, QA, and retailer traceability.

See our vision system in action:

Secure access

Control system access with user management and hierarchy

Comprehensive training

We onboard your site teams to confidently operate and expand the system, including training new SKUs or updating product specs.

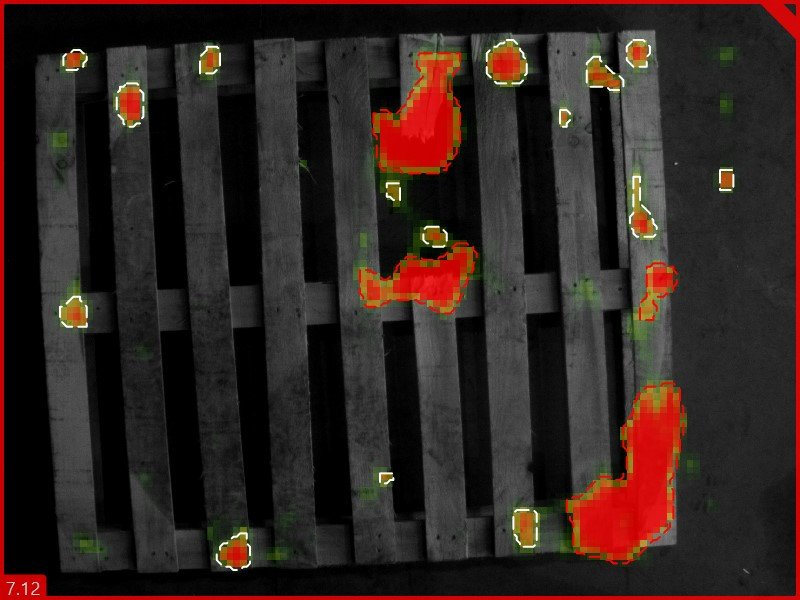

100% Quality with AI Laser Inspection

Take your quality to the next level with AI-powered 3D Vision Inspection of every product.

Using a combination of powerful optics, industry-proven vision technology, and embedded AI, the system captures detailed 3D images and analyzes depth information to detect subtle features and measure them against pass/fail thresholds.

Improve inspection reliability and throughput with AI and advanced imaging

Maximize operational efficiency with fast, easy deployment

Scale your automation with a flexible vision platform

Verify the quality of food products, including croissants, dough, meat and seafood.

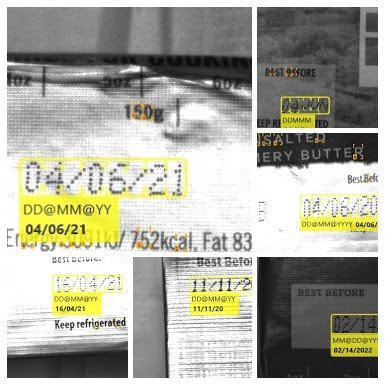

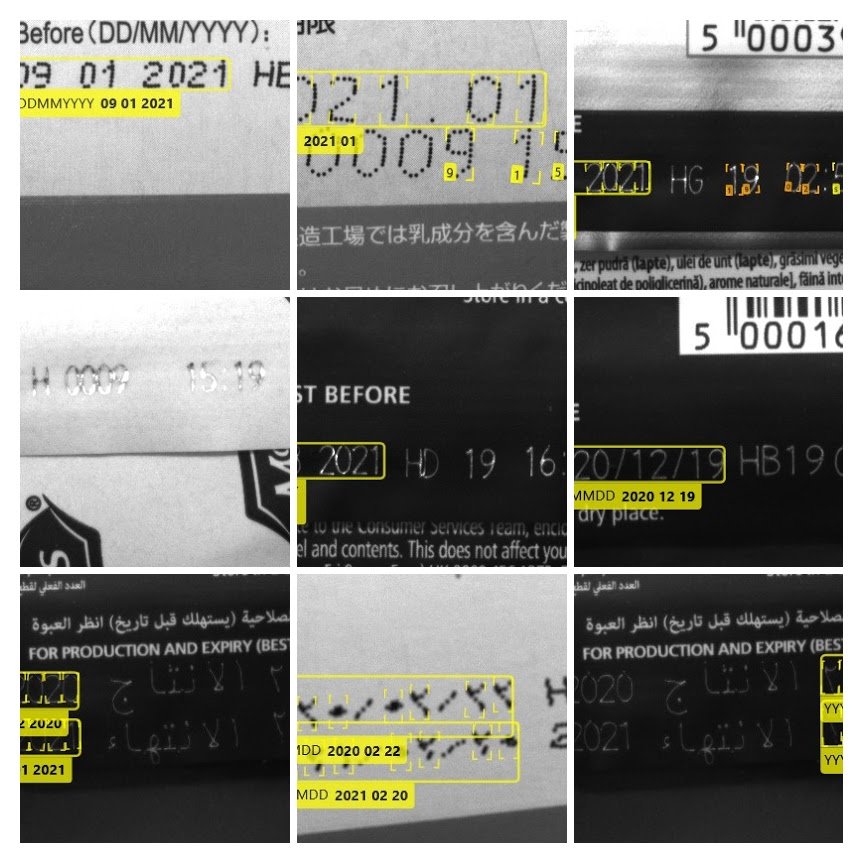

Date Code Verification with APRIL Eye

Close the loop and verify the date code printed on the pack with the world's most powerful AI vision system. Originally developed with a major UK retailer in 2019, APRIL Eye has two key use cases:

Scenario 1, you have a fully automated secondary packaging with no human visual inspection. Generally, humans are good at spotting missing or blurred codes. If no human will see a pack before it hits the consumers hands, assessment is critical to ensure code quality.

Scenario 2, you use printers outside of automated control. Most companies utilise automatic printer control, but if a printer breaks, a printer outside of automated control could be used, exposing the business to the risk of human error.

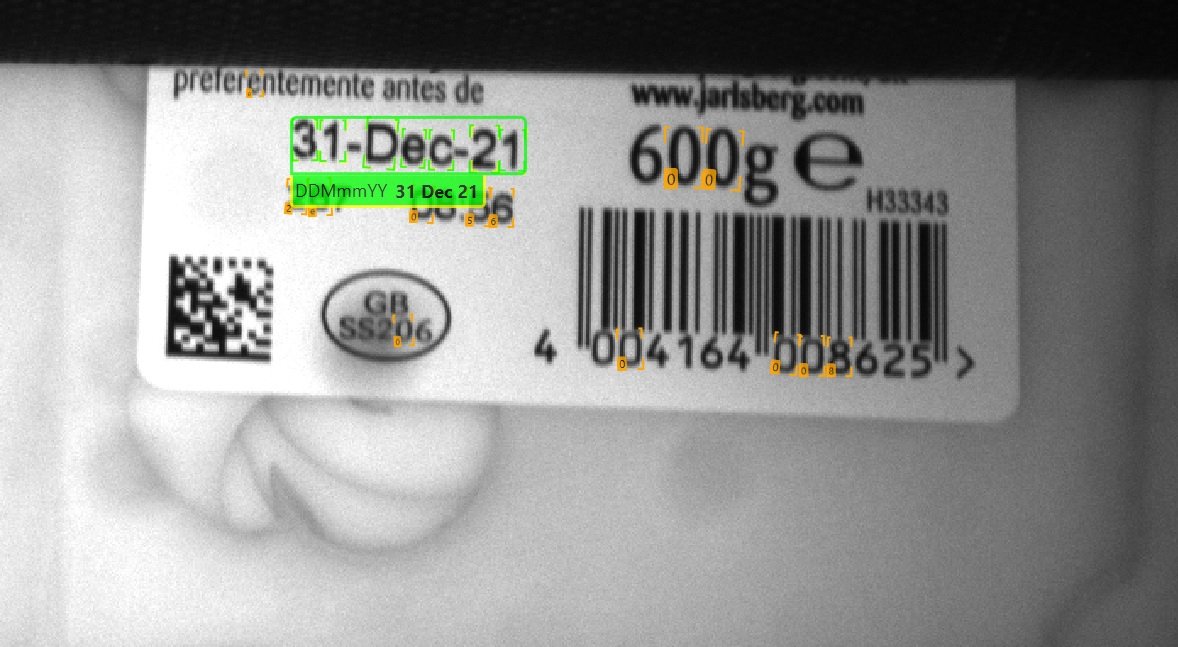

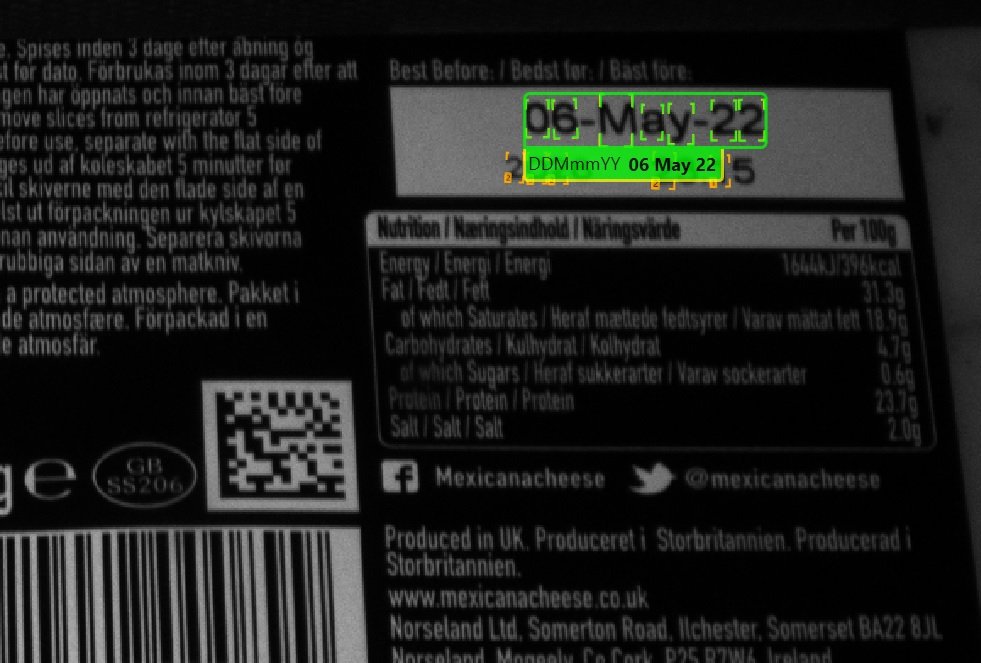

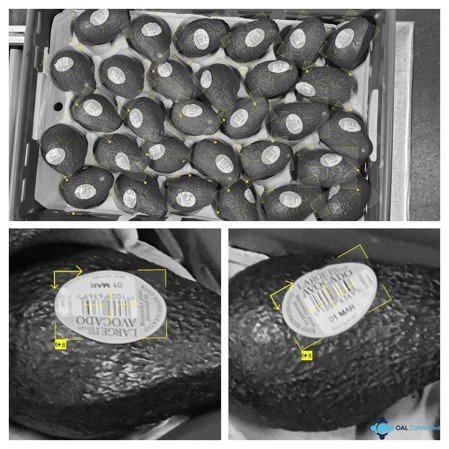

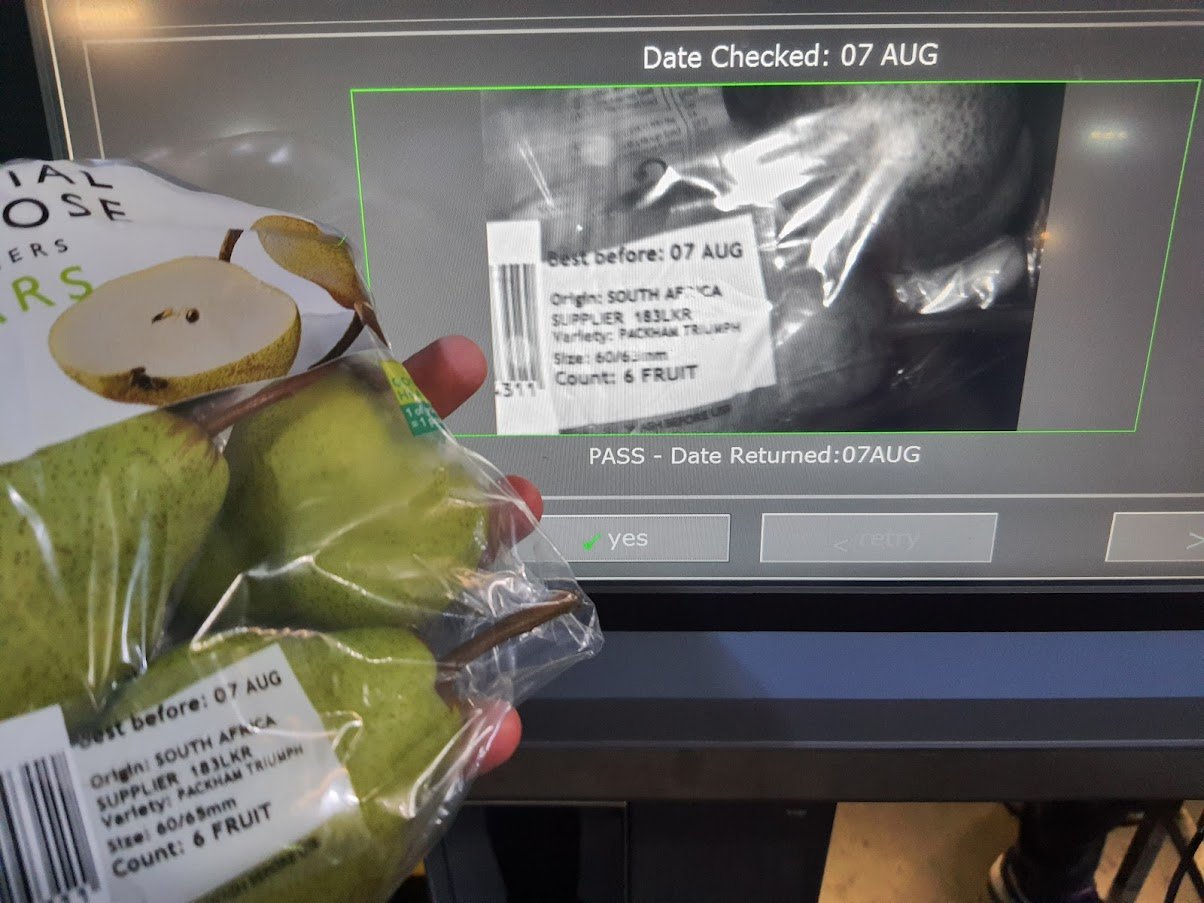

APRIL Eye (AE) Hand scanning

Take a picture of the date code using the hand scanner on the line terminal. The AE software will analyse the image, confirm the date code and verify against the running job. This check can be undertaken during job start-up checks and ongoing timed checks, effectively sampling print quality every 10 minutes.

APRIL Eye (AE) Online verification

A camera mounted on the packaging line takes a picture of every date code. The AE software analyses the image, confirms the date code, and verifies against the running job. If an error is detected, a signal is sent to stop the line or a pack reject system.

The image shows an example of an APRIL Eye-hand scanning check. The operator takes a picture of the printed date code with the hand scanner. AE reads the date code in the image “07 Aug” and verifies against the running job.

AI Label Verification

Capture an image of every pack and verify every element using APRIL Eye, powered by Cognex.

Verify the content of every label at rates up to 200 packs per minute (ppm) including:

Packaging artwork

Date code, use by or best before

Variable field information, including “Country of Origin” & “Grower”

Promo label presence and content

Finished product (if visible)

How does APRIL Eye work?

APRIL Eye combines machine learning and artificial intelligence to transform the traditional date code verification process.

Capture – Image taken by hand scanner, tablet or online camera

Analyse – AI vision engine reads, counts or classifies

Verify – Compares to job spec or target rules

Respond – Triggers reject, line stop, alert or log

How is APRIL Eye different to a normal vision system?

Traditional vision systems have relied on optical character recognition (OCR), designed to read specific characters. Due to the prevalence of inkjet printers in the food industry, which have a higher degree of variability, these vision systems have not been widely implemented as they have struggled with:

Varying fonts and sizes

Font distortion

Missing or incorrectly positioned text

Packing changes

OAL therefore developed APRIL Eye, which uses standard cameras backed up with an artificial brain to deliver a vision system that can deal with variations such as lighting, positioning, print quality and placement inherent in a food or beverage plant and read anything that is also legible to the naked eye. In this way, APRIL Eye eliminates errors, offers full traceability and protects consumers and your brand while at the same time reducing labour costs and waste.