Why were food recalls on the rise in 2024?

Food recalls have become an increasingly common headline in recent years, raising questions and concerns about the safety of what we eat.

2024 is one of the most disruptive years, seeing an increase of 10%.

Due to the increasing number of incorrect labelling, Incorrect date codes, and undeclared allergens, recalls are gaining more public attention than ever before.

2024 saw a notable rise in food recalls, with 127 reported cases—a 10% increase compared to the previous year. While this reflects improvements in detection and reporting systems, it also highlights the growing complexities of today’s food production and supply chains.

What were the key causes, and how can businesses reduce their risk? To explore these questions, we spoke with industry experts, including Faye Louch (OAL), Nic Sharman (Food Safety Consultant) and Mark Spurdens (University of Lincoln.

What are the top reasons for food recalls in 2024?

According to data from the Food Standards Agency (FSA), here’s a breakdown of the most common reasons for recalls last year:

Undeclared Allergens: 53 cases

Mislabelling, recipe changes, or cross-contamination during production led to allergens like nuts, dairy, or gluten being omitted from product labels.

Physical Contamination (metal, stones, packaging, glass, etc.): 25 cases

Foreign materials entered food during processing due to equipment wear, handling issues, or insufficient quality checks.

Pathogen Contamination (Salmonella, E. coli, Listeria): 23 cases

Results from harmful bacteria like Salmonella, E. coli, or Listeria contaminating food. This can occur due to improper handling, poor hygiene, or inadequate cooking and storage conditions.

Incorrect Use-By Date Codes: 9 cases

Human error or equipment failure causes wrong or missing date codes, leading to confusion over product safety and shelf life.

Food Contamination (Allergy-related): 10 cases

Cross-contamination with allergens during production, such as shared equipment or improper cleaning, leads to allergen residues in products not meant to contain them.

Wrong Labels: 6 cases

Arises from errors in packaging design or printing, such as using the wrong label or failing to update the label after recipe adjustments.

Supply Chain Counterfeits: 2 cases

Fake or unauthorised products infiltrate the supply chain, often due to weak supplier vetting, fraudulent activities, or lack of traceability measures.

Burn Risks (exploding cans): 2 cases

Defective products can cause pressure build-up or overheating when heated.

Incorrect Ingredients: 1 case

Occurs when production line errors or supplier mistakes lead to the use of unintended or mislabelled ingredients, potentially altering the product's safety or compliance.

Based on data released by FSA for “Allergy Alert and Food Alert”

So why are recalls on the rise?

The rise in recalls reflects progress in detection technology, testing sensitivity, and consumer reporting. However, it also underscores the challenges manufacturers face in navigating increasingly complex processes and supply chains. Key contributing factors include:

Reliance on Manual Processes

Human error can occur at critical points, particularly when systems rely on standalone or paper-based methods that aren’t fully integrated.

Growing Supply Chain Complexity

With diverse ingredients sourced globally, risks increase. Managing these intricacies with manual systems for allergens or labelling is particularly challenging.

Cost Pressures and Risks

The financial impact of recalls continues to grow. As Faye Louch, OAL Connected Trainer, explains:

"If a product is recalled due to a labelling error, the costs extend far beyond the fine. You also need to account for production costs, labour, ingredients, distribution, recovery, and disposal. These can significantly impact a business's bottom line."

Example Recall: Undeclared Allergen Due to Labelling Error

When a new ingredient is added to a product, it’s critical that all teams involved—product development, production, and technical —are fully aligned.

Here’s how a simple oversight can lead to a recall:

A food manufacturer introduces a new ingredient, such as almond flour, to enhance a product’s flavour. The internal team responsible for recipe changes notifies the labelling team, who create an updated version of the product’s packaging.

However, there are now two versions of packaging artwork: one declaring almond flour and one without. Unfortunately, not all of the old packaging is disposed of, and an operator accidentally brings the outdated version to the production line.

The error goes unnoticed until the product has already been shipped to retailers. A consumer reports an issue, triggering a costly recall

OAL’s automated label and date code verification systems prevent issues like this by ensuring complete artwork version control. Using technologies like 2D barcodes, we track packaging changes and prevent the use of outdated materials on the production line, verifying every piece of packaging.

How to stop a recall.

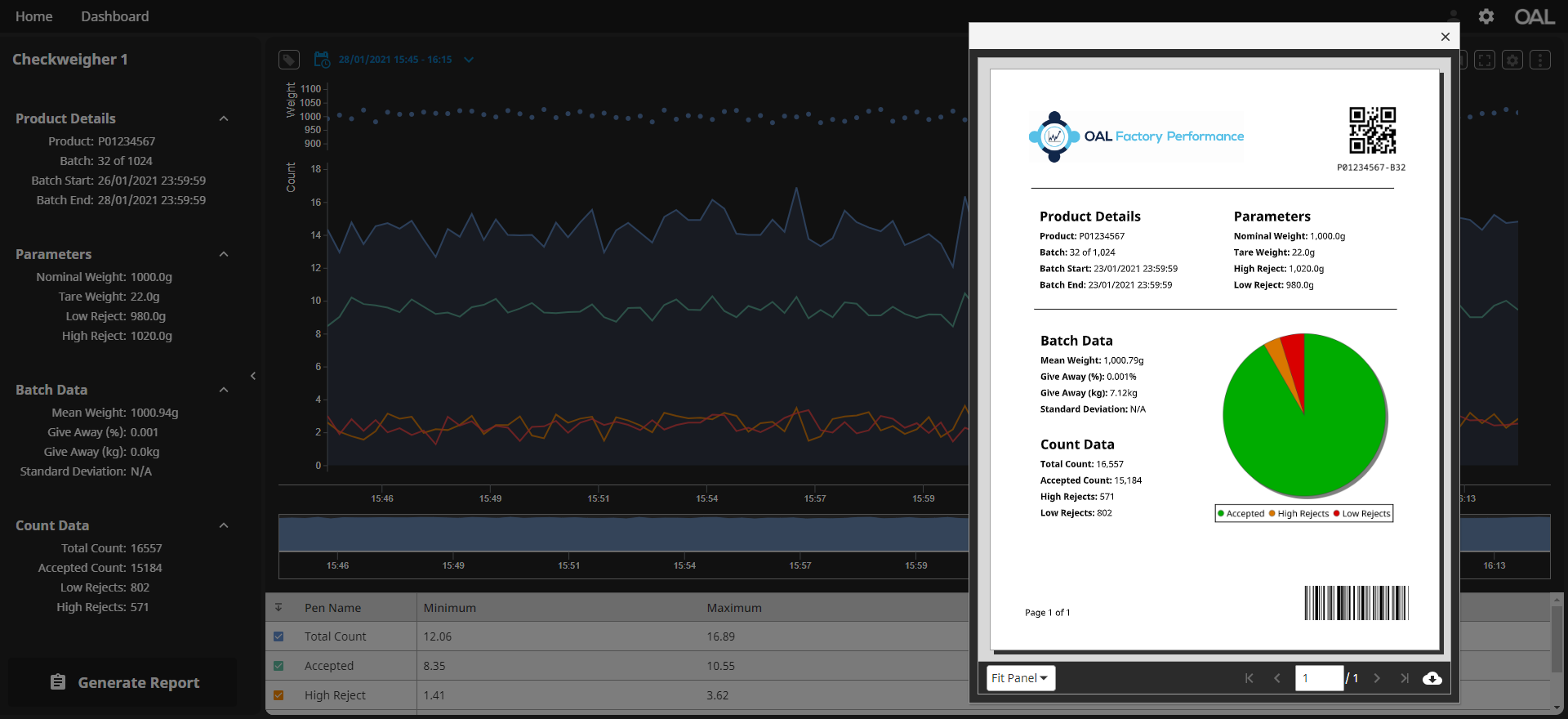

At OAL, we understand the challenges technical managers face in maintaining compliance while improving operational efficiency. We’ve partnered with leading food manufacturers to implement robust systems that reduce reliance on manual processes, enhancing both safety and traceability. Our approach includes:

Automation and Integration

By automating label and date code verification, we eliminate many sources of human error. Integrated systems ensure consistency across production lines, improving compliance and reducing risk.

Proactive Support

Our team collaborates with you to design tailored solutions, providing ongoing training and audits to ensure compliance with BRC and other industry standards.

Improved Efficiency

Our systems don’t just protect against recalls—they also enhance operational effectiveness, helping you achieve greater accuracy and productivity.

Leena Malde, Executive Chair of Wealmoor, shared her experience with OAL systems:

““The introduction of automated systems from OAL has completely changed our operations. Since its installation, we’ve been able to streamline our processes and prevent errors before they caused further issues, protecting our reputation, enhancing trust and confidence. We’ve also seen the significant opportunity in increasing efficiency and operational effectiveness.””

Is AI the Future of Food Safety?

AI technology is playing an increasingly important role in food safety, but it’s most effective when supported by robust processes. For example, AI cameras can verify product labels, but the data driving these systems must be accurate and up-to-date.

““Technology is readily available to read and verify labels but it’s imperative teams create a culture that maintains these systems and doesn’t switch them off!””

Forward-thinking manufacturers like Worldwide Fruit are already integrating their ERP systems with OAL’s label and date code verification technology. This ensures that:

Real-Time Updates: Production changes are immediately applied across systems.

Error Reduction: Human intervention is minimized, ensuring accurate checks every time.

Improved Traceability: A single source of truth provides end-to-end visibility and accountability.

By digitalising manual processes, manufacturers gain not only safety and compliance but also valuable insights into production trends, downtime, and efficiency.

Looking Ahead: Protecting Your Business in 2025

Recalls remain a sensitive and challenging issue, but with the right systems in place, they can be significantly reduced—or even eliminated.

At OAL, we’re here to support your business every step of the way, from designing and implementing automated solutions to providing training and ongoing support.

For more details on automated label verification, contact us by clicking the button.

Kick off your promotions with confidence

In the consumer goods industry, the ability to swiftly and accurately update packaging for seasonal events. Automated label verification systems, such as those offered by OAL, play a vital role in managing these changes efficiently.

Why you could benefit from an OAL Automated Verification System.

In the food industry, the ability to swiftly and accurately update packaging for seasonal events such as football tournaments, the Olympics, Christmas or Valentine’s Day is crucial. These occasions often require unique, event-specific designs that attract consumers and enhance brand visibility. Automated label verification systems, such as those offered by OAL, play a vital role in managing these changes securely and efficiently.

The power of the 2D barcode

M&S has adopted 2D barcodes across all its ranges. Typically the 2D barcode sits within the date code box.

But why? 2D barcodes provides food manufacturers with artwork version control.

This means the SKU can have the same 1D EAN barcode but different 2D barcodes, depending on the artwork.

So, artwork with a Team GB flag on has a unique 2D barcode compared to everyday artwork.

OAL’s claim to fame is introducing the first 2D code on pack for label verification. In 2006, we helped First Milk secure its cheese packaging by using 2D barcodes for verification.

18 years later, it’s surprising how many brands still don’t use it!

100% continuous and precise verification

Combining 2D barcodes with an autocoding system puts you in complete control of your packaging.

Your technical team controls which version is available to select on the line. Our system has two users sign off, so any change must be authorised for added protection.

They can also set availability so your promo artwork can only be used during a set date range.

Once the job is selected on the line, a camera will scan the 2D barcode of every pack to ensure you’re using the right artwork.

Here is an example case study of how Edwards the Welsh Butcher eliminated errors with OAL’s AI-driven verification system

But what if I don’t want to put a 2D barcode on my artwork?

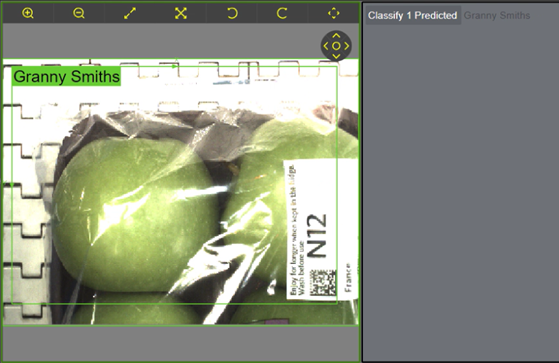

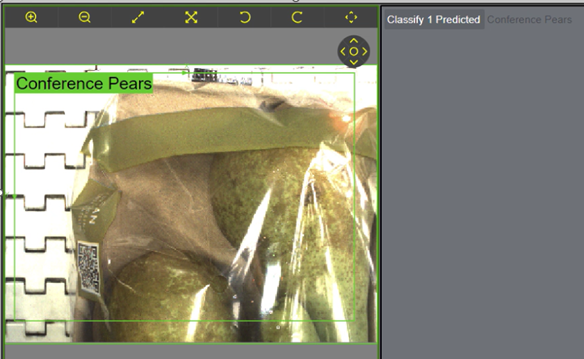

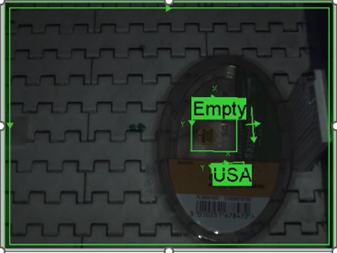

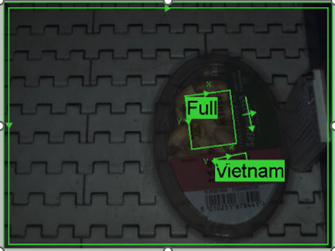

An alternative way to verify artwork is machine vision. We’ve been deploying powerful AI Cognex cameras that take a single image of a pack and can verify every detail. For instance:

Packaging artwork text e.g. seedless

Date code, use by or best before

Variable field information, including “Country of Origin” & “Grower”

Promo label presence and content

Finished product (if visible)

Key benefits of automated systems

Quick set-up and integration

These systems are easily integrated into existing workflows, ensuring a smooth transition to new packaging designs.

Allergen tracking

With advanced tracking capabilities, companies can manage allergen information accurately, even with frequent design changes.

Tailored alerts

Immediate feedback and alerts ensure any discrepancies are addressed promptly, keeping the production line running smoothly.

Conclusion

Seasonal events like Euro 2024, the Olympics or special holidays are opportunities for brands to engage with consumers through bespoke packaging. Automated verification systems are essential in managing these changes, ensuring accuracy, reducing errors and maintaining high standards. By leveraging such technology, brands can confidently embrace seasonal marketing strategies without compromising on quality.

OAL utilises its APRIL Eye technology to ensure that customers have the most reliable safety net available, capturing a plethora of required data and verifying at impressive speeds. OAL also helps food manufacturers integrate their ERP systems across a number of applications creating a single source of truth that businesses can rely on.

For more details on automated label verification, contact us by clicking the button.

9 key benefits of ERP Integration with your Packaging Line

Digital transformation within fresh produce and food manufacturing businesses requires enterprise resource planning (ERP) integration with manufacturing and shopfloor operations

Fresh produce and food manufacturing businesses on digital transformation programmes understand the importance of integrating enterprise resource planning (ERP) with manufacturing and shopfloor operations. This blog shares the key benefits of integration, highlights successful applications from other food manufacturers, and explains how the integration is achieved using the Ignition SCADA/MES platform.

Why integrate ERP with your manufacturing operations?

Food manufacturers can improve their profitability, agility, and efficiency by integrating SCADA and ERP. The integration adds real-time data to your ERP system, gives context to shopfloor data, and enables the coordination of schedules, orders, distribution, and more, helping your company comply with regulations, improve efficiency, increase transparency, and accelerate data availability and synchronisation.

If your systems are not integrated and are “siloed” you are likely to suffer from these issues:

Inaccurate information. Manual data input for OEE calculations skews efficiency measures. Teams can lose trust in data and question its reliability.

Higher operating costs. Reliance on manual double entry (sometimes more) of critical information.

Slow decision-making. Changes in customer orders or raw material shortages don’t reach key personnel in a timely manner. For instance, receiving a custom report the day after versus real-time notification.

Increased opportunity for error. Entering information in multiple systems increases the chance of re-keying incorrect data.

Decreased agility and ability to understand the full value stream. Departments and teams struggle to see the bigger picture. Improvements can be made to an asset or area but not the whole value system.

ERP integration will have a transformational impact on your manufacturing business, streamlining and providing critical real-time information. But can it deliver a payback? With rising wages and limited availability, the cost of lost hours and downtime is increasing.

A £50,000 investment needs to save 2,000 hours* per annum to deliver a 1-year payback or just 5.5 hours per day.

*Based on hourly wage rate of £25 per hour taking into account total cost of employment.

So how do we save those hours? Here are some benefits of ERP Integration to consider:

1) Data Integrity

Integration creates a single source of truth for your business. For label and date code verification (Autocoding), this means that you no longer need to manage two product databases. SKU packaging, data code and variable field (country of origin) data can all be held in your ERP.

2) Agile Scheduling

Changes in ERP scheduling or other scheduling software are immediately updated for operations. Time isn’t lost preparing for the wrong job.

In 2020, OAL installed a standalone label and date code verification system at Worldwide Fruit. In 2023, we completed a project integrating the label verification system with their ERP.

Target pack counts update throughout the day based on actual orders received in your ERP.

3) Agile response to customer orders and requirements

Update and respond to changes to customer order volumes and requirements in real-time.

At Driscoll's (formerly Berry Gardens) OAL integrated their packaging line control and provided an OEE system built on Ignition integrated with their ERP, Prophet. Their customer order quantities are updated throughout the day and now operations know as soon as they change!

4) Improved business insight & target-setting

Benefit from real-time information and generated by reports dedicated to your specific data requirements.

Yield and giveaway are key metrics for businesses packing expensive dairy and meat products. Management can see yield in real-time as opposed to a report the day after.

5) Enhanced collaboration with works order visualisation

Align technical, operations, engineering, marketing, and sales with shared real-time data. Receive scheduled works orders from your ERP and visualise works order progress through your factory, including real-time ingredient traceability and consumption.

When raw material delays or shortages occur, you can quickly pull together a new schedule based on what you have on hand and what you need to make. With a better understanding of your overall order pipeline, you can start towards strategies like “just-in-time manufacturing.”

6) Track raw materials and inventory through production

Inventory is an easy win when integrating SCADA and ERP systems. You can track which raw materials are in the warehouse, what you need to produce orders for a given day, and which finished goods will be ready for shipment once production is complete. If you find you are running low on raw materials, you can quickly shift production to another order before the lack of raw materials stops the line. Then, by tracking real-time production, you can trigger the re-ordering of materials and parts during production when inventory starts to get towards your order threshold.

At Premier Foods, Ashford, OAL’s SCADA and MES solution integrates with SAP to track raw materials and report real-time usage.

7) Lower operational costs

By using streamlined business processes and highlighting improved best practices through real-time data, you can also lower management costs through uniform and integrated systems.

8) Consistent cyber secure infrastructure

From the back office to the front office, all business activities will have the same look and feel, making training easier. Ignition features ultra-secure SSL technology and supports modern cyber security protocols such as federated identity infrastructure, multi-factor authentication (MFA), and single sign-on (SSO).

9) Reduce risk with the right product raw material validation

Integration to ERP can validate ingredient usage against live jobs and bill of materials in production. For example, to enable or disable the tip sequence to prevent incorrect materials from being introduced.

How to use Ignition to integrate your ERP with manufacturing operations?

ERP is an IT system, and SCADA is an OT system. Transferring data is difficult as OT and IT use different languages, and their data is stored and gathered in different ways.

Ignition makes the process of connecting SCADA to cloud ERP much easier. Ignition is a web-based SCADA, MES, IIoT, and HMI platform built on open standard technologies, and it is already designed to connect SCADA and OT with IT through an OPC UA server. Depending on the application requirements the integration can be achieved in four different ways.

1. Set up an API (Rest)

Provides a direct network connection between the ERP and the SCADA/MES for real-time, bi-directional information exchange.

OAL’s Label and Date Code Verification and APRIL Robotic Weighing systems have a standard Rest API for communicating with ERPs.

2. Shared Database Table

A database table is established as a common communication point. The ERP system and the SCADA/MES system use this table to exchange information.

OAL has completed many integrations using shared SQL tables. For instance, the Premier Foods SCADA system at Ashford uses shared SQL tables.

3. Stored Procedure or “View"

A stored procedure or “view” is installed in the ERP database for the SCADA/MES application to read and/or modify a specified subset of data from the ERP system.

Where possible we avoid this methodology as it can be difficult to ascertain the origin of a new or changed item of data.

4. Export CSV or XML File (Flat File)

The ERP writes a .csv file to a common location. The SCADA/MES software regularly looks for new files containing needed information. For instance, exporting a CSV schedule of works orders and upload to the SCADA/MES to provide a schedule. This approach is common if you’re running a legacy ERP with no connectivity, for instance, we have used this approach to integrate systems within the UK’s largest flour mill.

We would love to share more with you about the benefits of ERP Integration.

If you would like to discuss more about how ERP integration would be beneficial to your operation, then reach out to the OAL team.

Five challenges to running a profitable fresh produce business...and how automation can help

Fresh produce businesses are facing a “perfect storm of challenges” tackling erratic weather and soaring input costs exacerbated by shocks including Brexit, Covid and the cost-of-living crisis. Discover how automation helps fresh produce businesses succeed.

According to the Grocer, fresh produce businesses are facing a “perfect storm of challenges” tackling erratic weather and soaring input costs exacerbated by shocks including Brexit, Covid and the cost-of-living crisis. This blog explores how automation emerges as a key ally, bolstering success in this dynamic sector.

Over the last 5 years OAL has helped fresh produce businesses automate including key industry players such as Driscoll's, MM Flowers, Wealmoor, and Worldwide Fruit with a combined turnover in excess of £3bn.

Learn more about Worldwide Fruit’s journey here

Fresh Produce Challenges

1 - Limited labour availability

Key workers, essential during peak months, are limited in number by UK government rules for “Special Workers”. Automation can significantly boost productivity, offsetting these limits and upskilling local talent.

2 - Rising labour, raw material and energy costs.

Input costs have risen across the board. And with the minimum wage set to increase from £10 to £11.45, they’ll continue to rise in 2024. Automation can curb and even reverse the trend of rising costs in the industry.

3 - Supply chain complexity

Natural disasters and weather shocks mean businesses must maintain flexibility of supply and be able to react fast to any changes.

4 - Product diversification

Experimentation with new packaging formats to drive revenue and profitability with key targeting for snacking. Automation gives you the confidence to introduce more complexity like artwork variations as each can be easily tracked and verified.

5 - Retailer requirements

Retailers' stringent requirements for food safety, product integrity and traceability can be effectively met through automated solutions including vision.

Is automation and digitalisation the answer?

Whilst automation isn’t a “golden bullet”, it’s a key enabler. People are the heart of fresh produce businesses and it’s their ability to adopt and benefit from technology which is critical to success. At OAL we promise to make it easy to adopt new technologies, for instance, our best-in-class 24/7 support and training.

We’re big believers that modern fresh produce businesses will be digital (no paperwork), and integrated (systems talking to each other) and artificial intelligence (AI) will have a significant role to play.

Tackling labour availability and scarcity with a major productivity boost.

Creating a modern, digital working environment can empower shop floor operations and help recruitment. “Digital natives” prefer iPads and tablets to paper and pen, so will prefer a modern automated packhouse making recruitment an easier process!

Automation can also simplify and shorten workflows with a big impact on the bottom line. Take grower code changes. If you’re manually setting up printers, each grower change takes up to 5 minutes as an operator keys the information into the printer and stops the line. Multiplied by 30 changes per day across multiple lines, it can be a costly source of downtime. At the UK’s largest avocado packhouse, OAL has helped them reduce changeover times from 5 minutes to 2 seconds, a saving of approximately 10,000 hours per annum across all lines.

OAL customers have a “Grower Change button.” They simply load a SKU, and click the button to change the grower information from a pre-defined list on the fly!

But it doesn’t end there! With ERP integration, we can pull this information directly from the works order. Talk about a time saver!

Meeting and exceeding retailer requirements.

100% Packaging verification. Automation can help reduce human error, resulting in a higher-quality product that meets customer expectations consistently. The aim is 100% verification of all pack formats (flow wrapper, PLU, etc.)

For more information about how OAL can help you achieve 100% packaging verification, read our recent blog on “Top 10 AI Verification Quality Checks for Food Packaging”

Business agility with a single source of truth.

Change is a fact of life in the food industry! We can build the capability to react fast and effectively. By integrating systems together, fresh produce businesses can create a single source of truth. Any changes are instant and updated across all systems giving you confidence in your slick operations.

Want to learn more? Worldwide Fruit partnered with OAL in 2020 to automate its packhouse operations. Starting with label and date code verification, we’ve worked together to integrate their ERP system.

If you would like to discuss beginning, or enhancing your automation journey, please reach out to the OAL team today.

OAL are joint hosting an event with the University of Lincoln to talk about automation and sustainability. Interested? Register your interest here.

Top 10 AI Verification Quality Checks for Food Packaging

AI has the potential to transform every process in every industry; the secret is not to simply view it as what manual processes can AI replace, but how AI can transform what you do.

The world of AI has exploded in recent years and whether it excites you or scares you, we cannot ignore the transformational impact that it is having. AI is touching everyone, from personalising our online shopping experiences to powering natural language chatbots. From self-parking cars to intelligent navigation, from editing photos we take on our smartphones, to transforming the diagnosis of major illnesses.

AI has the potential to transform every process in every industry; the secret is not to simply view it as what manual processes can AI replace, but how AI can transform what you do.

Here we take a look at our top 10 verification checks, where AI cameras can help you.

Rule #1: AI + camera technology = quality game changer!

Original 1D barcode verification in 2001

For decades, the quality control of packaging and labelling has been a manual task, reliant on human attention to detail and often a factor that slows down the speed of the production line.

In 2001, we introduced the first barcode verification system with Tesco and Bakkavor.

In 2019 we introduced APRIL Eye, the world’s first AI-based date code verification system.

Prior to that there had been a reluctance as OCR vision couldn’t handle the variation of the fast-moving food industry.

By combining AI with vision camera technology, the game has changed. The best way to understand the impact that AI-powered cameras can have on packaging and labelling quality assurance is through real-life use cases.

1) That’s not an apple!

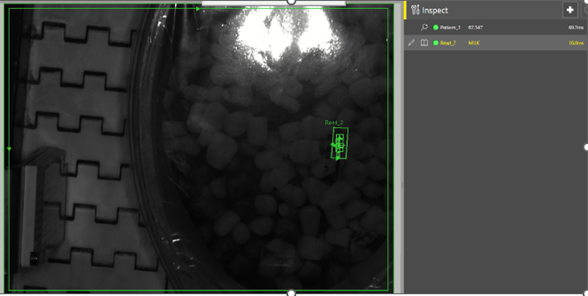

The worst nightmare - an item placed in the wrong packaging. AI-powered cameras are able to see beyond clear packaging and recognise the items inside. Is the item in the apple packaging actually apples? Or are they pears?; or maybe even the wrong type of apples? – the AI-powered camera can spot this.

2) Where are my croutons?

When there are multiple components required to be placed inside the packaging, a key quality step is to ensure that everything is included.

Verify the presence of components like croutons in bags of salad.

3) I can’t eat that without a fork

You’re packing a meal kit; has everything been included?

Verify the presence of objects like forks and spoons.

4) Where were these made?

Read and verify printed text on the packaging.

Check the country of origin matches the works order.

Conduct multiple checks simultaneously to include the presence of the finished product.

6) Are we on promo?

An AI camera can check the presence and content of a promo label.

7) Check allergens on WIP product

Ensure WIP product brought to the packaging line is correct by reading the printed information on the film.

8) Is the lid on tight?

With AI, you can verify every product to ensure rare events like bad lidding is caught in the factory.

9) Is the seal intact?

Verify the seal integrity of finished products using AI cameras.

10) Italian or cheesy?

The label on the bread says “Italian”, but is it really? Checking that the right type of bread is in the correct packaging with the right label is another great example.

Leveraging AI To Make A Big Impact

These are just some of the areas where AI-powered cameras and packaging and label verification solutions are having a big impact on food manufacturing. Yet this is only scratching the surface of what is now possible.

Have you considered ERP integration? By integrating your ERP with line devices you can make the most of AI to ensure your business is running off one single source of truth.

We can help analyse your process to understand the impact AI cameras can have on your quality. If you would like to discuss any of the use cases please do get in touch.